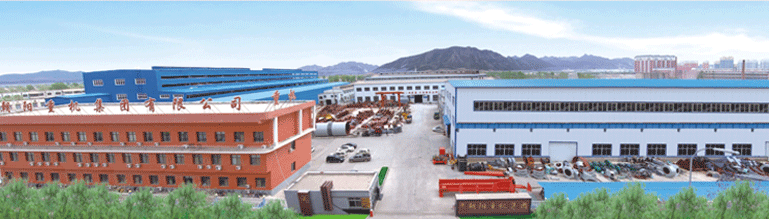

Chaoyang City, heavy machinery factory

Chaoyang Heavy Machinery Group Co., Ltd. (Chaoyang City, heavy machinery factory), located in Chaoyang City, Liaoning Province, registered capital of 48 million yuan. Building materials machinery industry key enterprises, under the Chaoyang heavy building materials Machinery Manufacturing Co., machining, metal structure, heavy steel, large gears, electronic control equipment, metal wear-resistant materials, import and export companies, machinery companies and other nine independent sales legal entities, Chaoyang heavy machinery factory as the core product design and development, manufacturing, equipment installation and after-sales service, is the production of cement, metallurgical machinery and equipment consisting mainly of large-scale comprehensive equipment manufacturing enterprises, Northeast one of the largest cement equipment manufacturer specializing in the region. Total assets of 850 million yuan, employees 1863 people, covers an area of 800 mu, building area of 15 thousand square meters. In 2007, the output value of 1.56 billion yuan, profits of 117 million yuan, asset-liability ratio of 45%. Major equipment companies Cylinder lathe: maximum processing capacity of ¢ 6000 × 18000mm, carrying 150 tons. Barrel special drilling equipment: horizontal power head, drilling, boring and reaming, cylinder size is not restricted. Automatic roller Group: Cargo 190 tons. M1380 Grinders, Cylindrical: the maximum processing capacity of ¢ 800 × 5000mm. CQ521000 eight-meter vertical car: maximum processing capacity ¢ 10000mm. T6216 BORING MACHINE: The maximum processing capacity of ¢ 250 × 6000mm. 1.25m slotting. ZFW505 ten meters hobbing machine: Max machining diameter 10000mm, modulus 45mm. 2m hobbing machine: Max machining diameter 2000mm, modulus 45mm. BQ2031 Gantry Planer: maximum processing capacity of 3.15 × 8mm. X2116 gantry milling machine: the maximum processing capacity of 6000 × 1600mm. X2010 gantry milling machine: the maximum processing capacity of 1000 × 3000mm. CW61100 horizontal lathes: maximum processing capacity of ¢ 600 × 8000mm. Flame cutting equipment: Japan imports NC6500 CNC cutting machine, cutting table 6500 × 20000mm. Japan imports NC5000 CNC cutting machine, cutting table 5000 × 15000mm. Japan imports NC2500 Optical cutting machine, cutting table 2500 × 10000mm. Above cutter plate thickness are 6-110mm. Planing machine: B81120A barrel plate planing machine: two sets of steel planing length L = 12000mm Bending: German imports PSIO coiling machine, cold roll maximum size of 110 × 4000mm. Steel pre-treatment equipment: Use of physical methods for cutting steel embalmed before. Welding equipment: A variety of AC and DC manual arc welding, TIG welding machine, semi-automatic gas shielded welding, submerged arc welding operation of various machinery (imported from Sweden three), to be completed steel docking cylinder straight seam, girth inside and outside welding and other work, the largest processing size ¢ 4500 × 12000mm. Stamping equipment (total of more than 30): You can complete a variety of pressure-shaped structural member, bending, stamping, blanking and so on. Large casting and forging and heat treatment equipment: 10 t electric arc furnace, a 10m Pit carburizing furnace NC 5 tons electric arc furnace, two sets High frequency quenching machine IF quenching machine. 10 tons cupola, a Salt bath heat treatment furnace 1000 kg air hammer, a 5 tons trolley type annealing furnace 1500 kg forging machine, a 10 t trolley type annealing furnace. Germany 250 tons presses, a Far-infrared heat treatment machines. Heavy lifting, shipping equipment: 75 tons of three bridge crane 160 tons a bridge crane <75 ton overhead crane. The main products are crushing equipment (jaw crusher, fine jaw broken machine, hammer crusher, impact crusher, single-stage hammer crusher, double rotor impact crusher, roll crusher, double roll crusher machine, vertical shaft crusher, vertical chain crusher, cone crusher, reversible double counterattack hammer crusher, roller press), grinding equipment (ball mill, raw mill, cement mill, high fine ball mill, wind swept coal mill, pendulum mill, rubber ball, ceramic ball mill, since the mill, vertical mill, wet lattice-type ball mill, overflow ball mill, rod mill, mill run), drying equipment, separator device preheating device (cyclone preheater, grate heating machine, vertical preheater), machinery and equipment kiln, rotary kiln equipment, cooling equipment (Rotary coolers, grate cooler, cooler ring with cooler, vertical cooler), mixer (or granulators) device, as the ball device (making the ball machine, ball press machine, drum granulator), round roll, sieving equipment, filter equipment, conditioning tower equipment, various feeder devices (disc feeder and stoker, rigidity and elasticity impeller feeder, single-tube and twin-tube screw feeder, screw feeder single overflow pipe, plate feeder, to the mining machine), processing equipment (drum Permanent dry sorting machine, permanent magnet drum magnetic separator, flotation machine, spiral classifier, filter, high-frequency vibration sieve, thickener), vibrating screen equipment (circular vibrating screen, vibrating screen, hot griddle, cold griddle), hoist equipment, conveyor equipment, stacker-reclaimer equipment. Annual production capacity of 120,000 tons of machines and structures, steel castings 50,000 tons. Enterprises with sound quality management system, products are sold in 27 provinces and autonomous regions, with import and export operation rights, the main exporting countries Brazil, Angola, Russia, Vietnam, Korea, Indonesia and Mongolia and other countries.